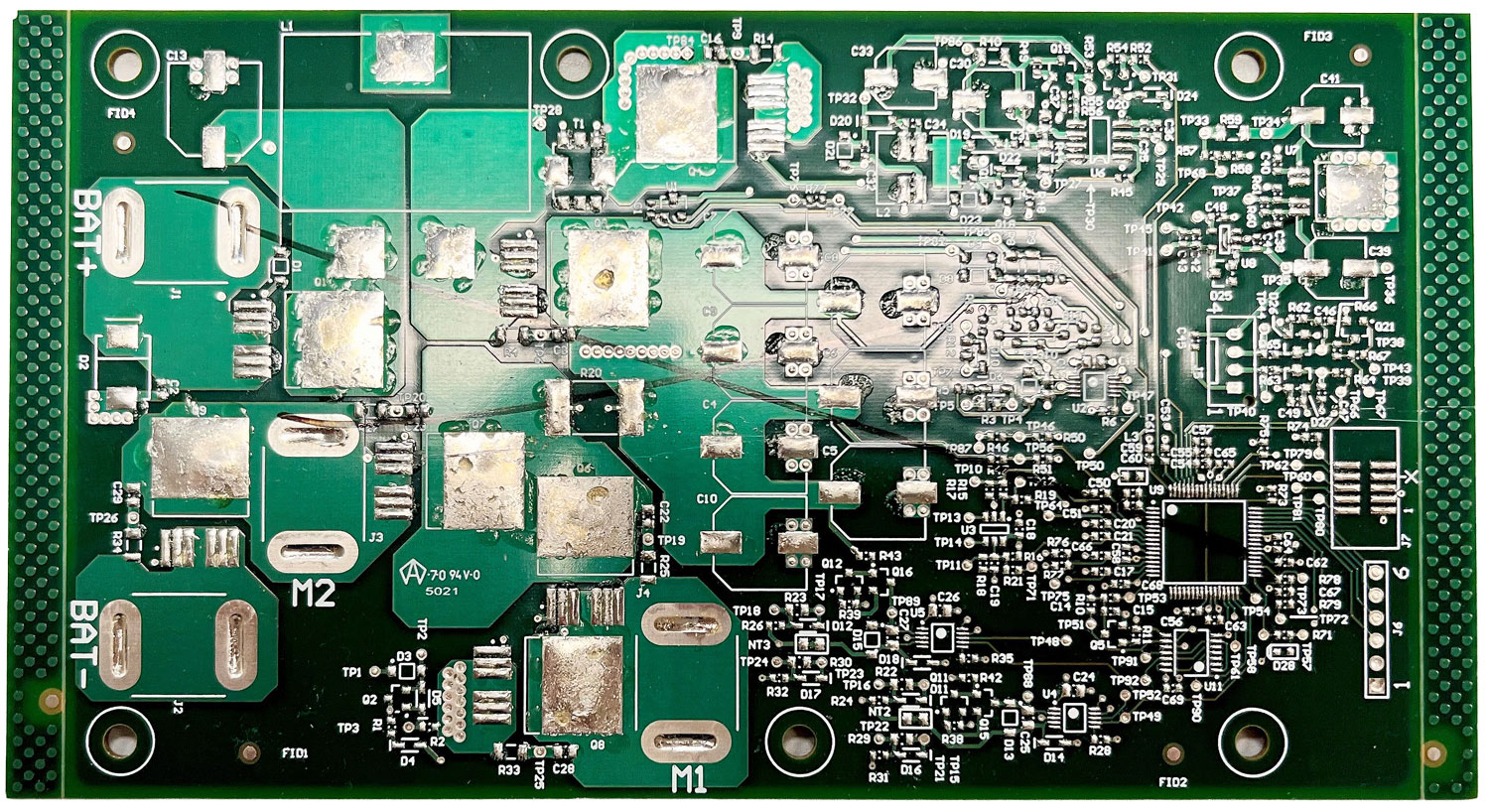

When designing a printed circuit board (PCB), one of the most important decisions you’ll make is determining how many layers your board requires. At Quantum Controls, Inc., we specialize in assembling PCBAs with anywhere from 2 to 32 layers, ensuring our customers get the right solution for their application. But how do you know how many layers your design needs? Let’s break it down.

What Determines PCB Layer Count?

Several factors influence the number of layers in your PCB design. Here are the most critical considerations:

1. Circuit Complexity & Component Density

- Simple designs like basic analog circuits can often use a 2-layer PCB.

- Complex designs with microcontrollers, FPGAs, or fine-pitch BGAs require more routing space, often 4 layers or more.

If your board has high component density and limited surface area, adding layers is the most efficient way to handle all the necessary signal routing.

2. Signal Integrity & High-Speed Requirements

Modern designs often include high-speed digital signals such as USB 3.0, HDMI, PCIe, or DDR memory interfaces. To maintain signal integrity:

- Additional layers allow for controlled impedance.

- You can dedicate layers for ground planes and reference planes, reducing crosstalk and EMI.

High-speed designs typically start at 4 to 6 layers, with some requiring 8 or more.

3. Power Distribution

Stable power delivery is critical in complex electronics. Inner layers dedicated to power and ground planes help:

- Reduce voltage drops

- Lower EMI

- Improve overall system reliability

This is one of the main reasons designs jump from 2 layers to 4 layers and beyond.

4. Size & Form Factor Constraints

If your product must be compact but still contains numerous components, more layers allow you to keep the board small without compromising routing. This is common in medical devices, aerospace electronics, and IoT products.

5. Thermal Management

Extra layers can help with heat dissipation, especially in power electronics or high-current applications.

6. Reliability & Regulatory Requirements

Industries like aerospace, automotive, and medical often demand higher layer counts for improved shielding, redundancy, and compliance with EMI standards.

Typical Layer Count Recommendations

- 2 Layers: Simple, low-speed designs with minimal components.

- 4 Layers: Standard for most moderate-complexity designs, offering dedicated ground and power planes.

- 6 to 8 Layers: High-speed digital or mixed-signal designs requiring excellent signal integrity.

- 10+ Layers: Advanced systems like networking gear, RF boards, and complex computing systems.

- 32 Layers: Extremely dense, high-speed, mission-critical systems (servers, telecom, aerospace).

Why Partner with Quantum Controls, Inc.?

At Quantum Controls, we have the expertise and equipment to assemble PCBAs with 2 to 32 layers, meeting the demands of everything from simple devices to mission-critical applications. Our team understands how layer count affects cost, manufacturability, and performance, and we work closely with customers to optimize every design for quality and reliability.

Need help deciding how many layers your PCB requires? Contact Quantum Controls, Inc. today. Let’s design and build a board that meets your performance, size, and budget requirements.

Visit us at www.quantum-controls.com to learn more about our PCB assembly services.